Pipes and Flanges

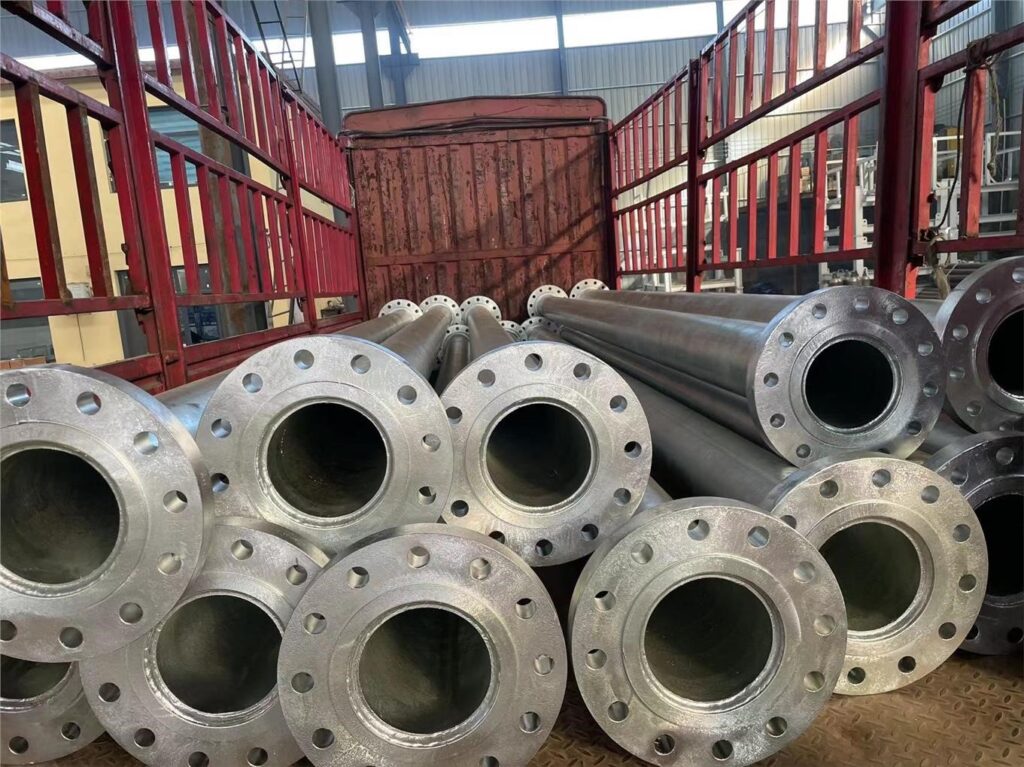

Flanged Steel Pipes

Steel Material Grade: ASTM A123 Schedule 80 with welded flanges drilled to ASME B16.5 Class 600.

Specialised welding

Our factory provides specialized top-tier welding on different steel grades to ensure quality products are supplied. Strong and smart welding is paramount to high pressure industrial working environment. All pipes undergo rigorous quality checks before being released from the factory and clients are guaranteed quality products.

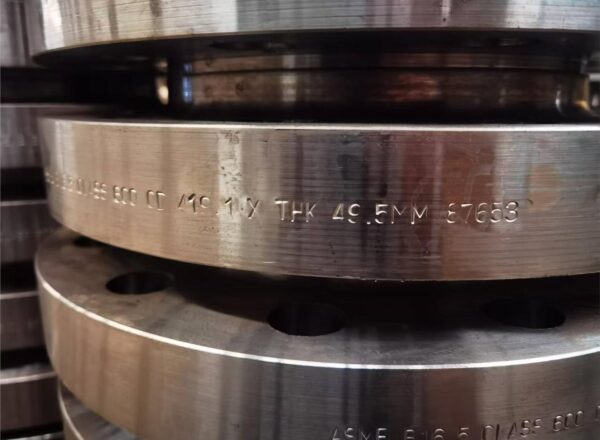

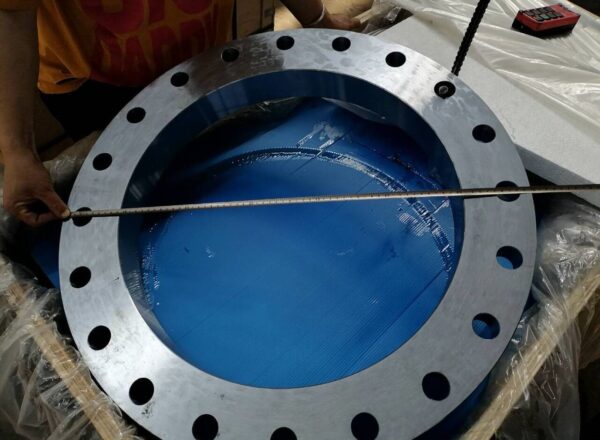

Flanges

BMEL supplies Mild Steel, Carbon Steel, Stainless Steel and Galvanized Flanged directly from factory. Flanges play an important part in water reticulation, connecting several components and equipment such as steel pipes, HDPE pipes, Valves and Pumps. Flanges are available in different steel grades and drillings and manufactured to end-user specifications. We do have local and international manufacturers that have partnered with us to meet different industrial requirements.

Flanges slip on (so), ASME b16.5 class 150, fullface (ff), schedule 40, Bore Cast Steel, ASTM A105 smooth finish.

HDPE and PTFE lined pipes and fittings

BMEL supplies HDPE and PTFE lined pipes and fittings. The interior surface is coated or lined with HDPE or PTFE material that is known for excellent chemical resistance, low friction properties and high temperature resistance. For Mining slurry rubber lined pipes and fittings need constant repair as rubber is eroded by debris under high pressure. HDPE or PTFE lining guarantees long life and less repairs of pipelines, this improves company savings and investments.

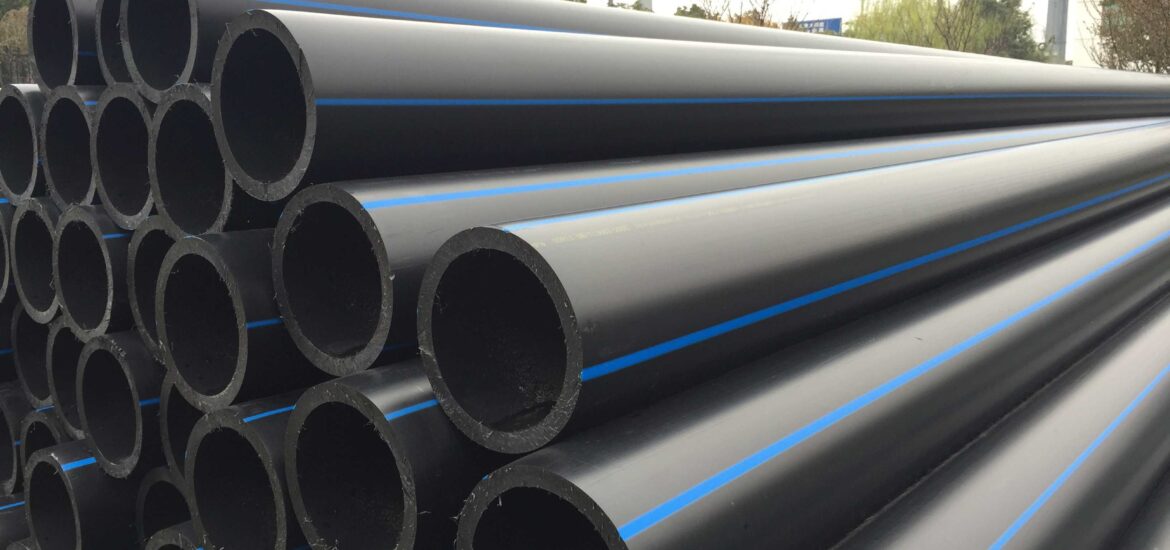

HDPE Pipes

BMEL supplies HDPE pipes for enhanced water reticulation and mining slurry. These pipes are highly abrasion resistant and mostly suitable for industrial and mining application. These are available with butt fusion stub ends and rings (flanges) and plain ends. Pipes are also available in different sizes and flange drillings to suit end-user specifications.

Flanged HDPE Pipes

Plain End HDPE Pipes

Ductile Iron Pipes and Fittings

Ductile iron, having various technical names while also known as ductile cast iron, nodular cast iron, spheroidal graphite cast iron (SG CI) and spherulitic graphite cast iron. Whilst most varieties of cast iron are brittle, ductile iron has higher ductility among which means having greater impact and fatigue resistance, due to its nodular graphite inclusions.

Advantage of Ductile Iron Pipes

▪ High Tensile strength, good elastic module and excellent ductility, making it suitable for high stress applications where pressure surge may be experienced.

▪ High corrosion resistance with external metallic zinc & finishing coatings.

▪ Excellent hydraulic flow.

▪ High working pressure comparing to other types of pipes.

▪ Ease of installation.

▪ Long lifetime.

▪ Can accommodate ground movement.

Main applications of Ductile Iron Pipes

▪ Drinking and irrigation water networks.

▪ Sewerage networks.

▪ Fire fighting systems.

▪ Water-cooling systems including Sea-water cooling.